Barrel Profiling Technology

Consistently achieving specific organoleptic targetsNext up in our Oak 101 Series, we are going to take all the chemistry you learned in the last two blog posts and explore how to use it to get a consistently toasted barrel – time after time. Why is this important? Because what a winemaker wants even more than a great tasting barrel, is a great tasting consistent barrel. When they fall in love with a barrel, they expect it to taste the same every year. As a cooper, one of our biggest responsibilities is to deliver on that expectation, and we take it very seriously.

Gone are the days when coopers toasted barrels using only sight and smell. Oak science has proven that color is not a direct indicator of flavor. The same level of color can be achieved via a short or long toast by adjusting the toasting temperature, which leads to very different chemical transformations.

Instead, in 2002 we developed a proprietary method of consistent toasting that we call …drum roll please… “Profiling”. Profiling is our process of using specific time and temperature curves, plotted on a graph, for our coopers to follow during toasting to achieve consistent results. The two most important benefits of our proprietary technology are 1. the toasting curve which allows us to develop specific flavors and 2. the consistency it allows us to achieve in toasting. For each unique time and temperature curve, or Profile, we target a defined combination of flavors, and can repeat the toast with extreme accuracy barrel-to-barrel and vintage-to-vintage.

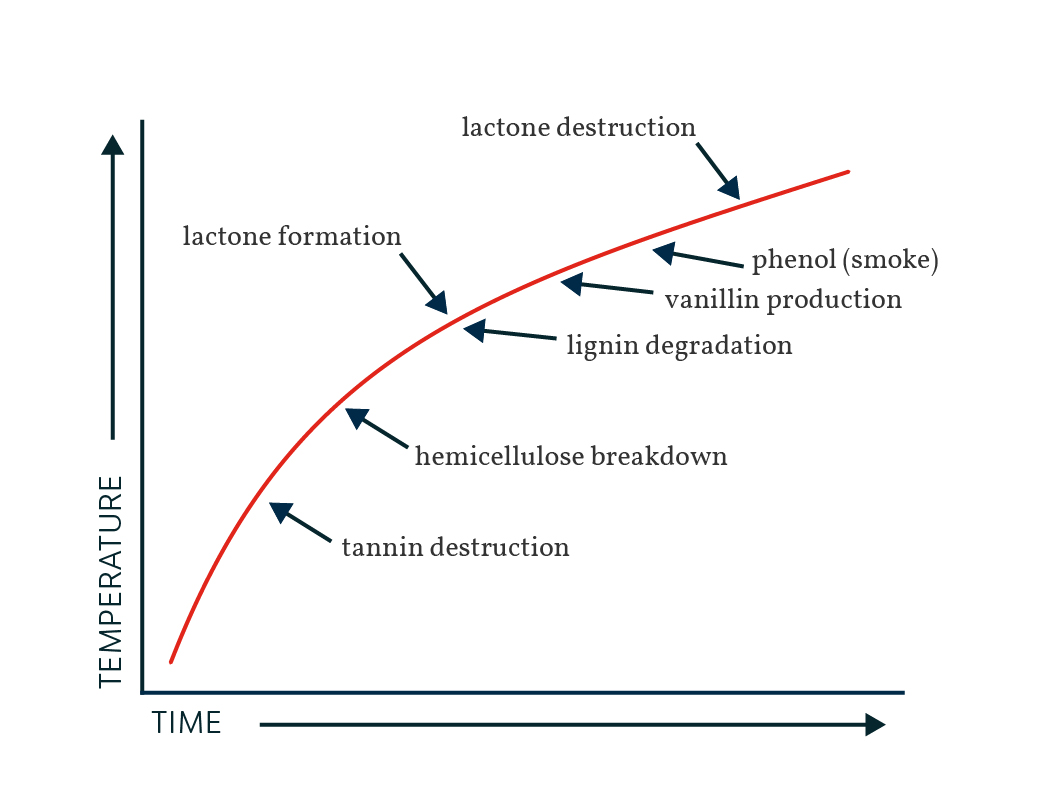

This is that same time and temperature graph we introduced you to in our last post. Quick review – different temperature equates to different amounts of energy and different time also equates to different amounts of energy. Think of us as toasting chefs, varying the amount of ingredients (time and temperature) to get the flavors, aromas, and mouthfeel we are looking for in the finished product.

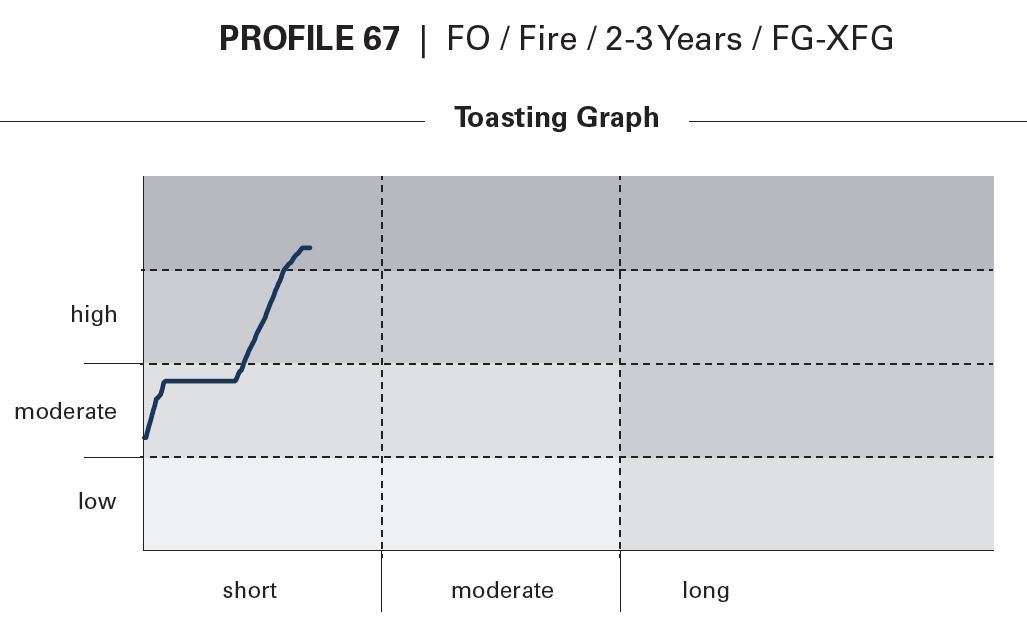

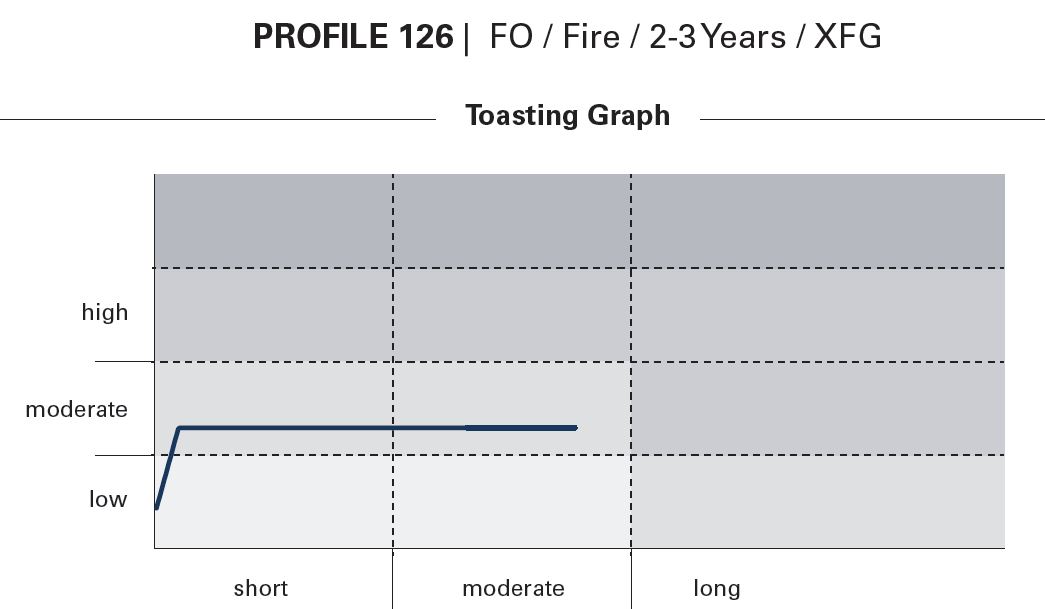

Let’s get a bit more specific. Here are the toasting graphs of our Profile 67 and Profile 126.

These two curves could not be more different, right? Profile 67 is toasted for a short time, with high heat that ramps up quickly. This time/temp combo retains tannin, caramelizes wood sugars, and delivers some roasty flavors. Because of this, Profile 67 is a great barrel for aging medium- to full-body reds over a long time.

On the other hand, take Profile 126, which is toasted at a lower temperature for a longer amount of time. Profile 126 breaks down a lot of tannin, which contributes to a softer mouthfeel. It also integrates with the wine quicker (thus requiring less aging) and delivers sweet oak flavors. Profile 126 works well on medium and light body reds, not dominating the fruit.

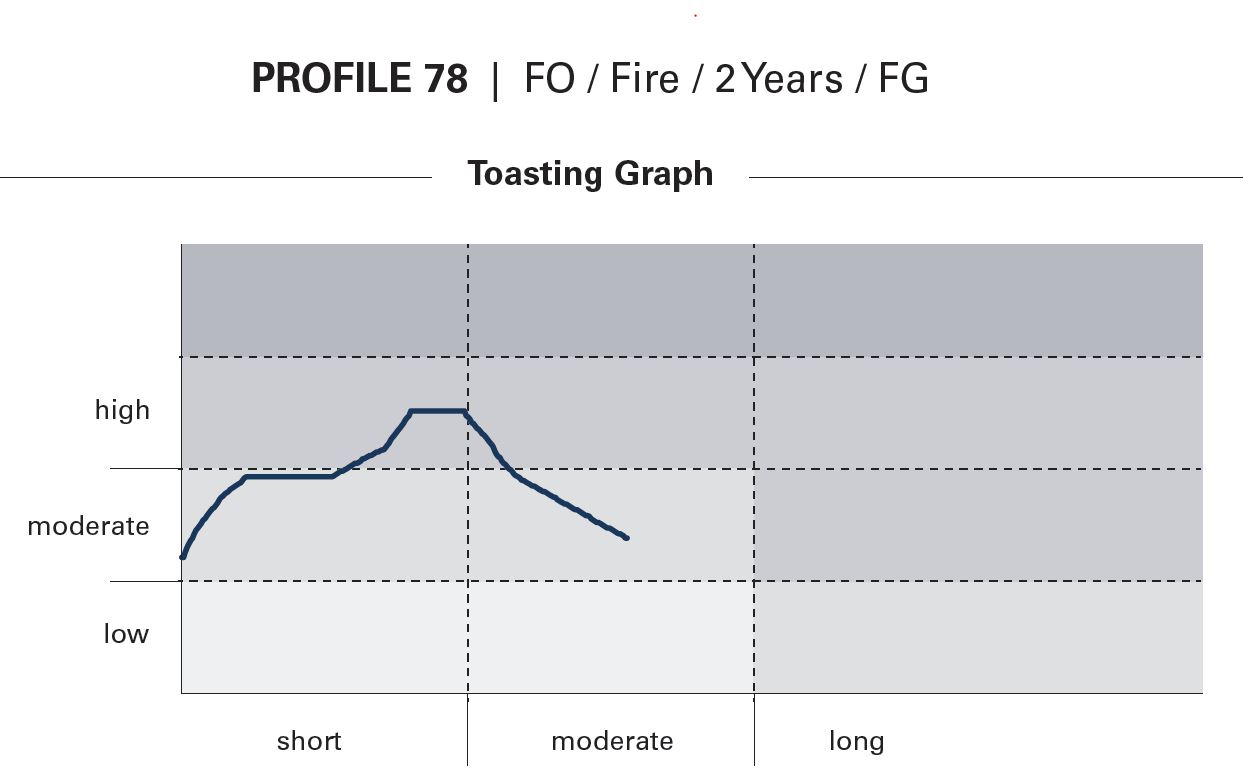

These examples illustrate how varying the time and temperature changes the shape of the toasting curve and creates two very different barrels in terms of flavor, aromas, and texture. Since World Cooperage developed our Profiling technology, we have created 150 unique Profiles. When we say we probably have a barrel to meet your organoleptic goals, now you know why! Here are a few other Profiles to show you some additional toasting curves.

Profile 78

Spice and dark characters, roasty notes.

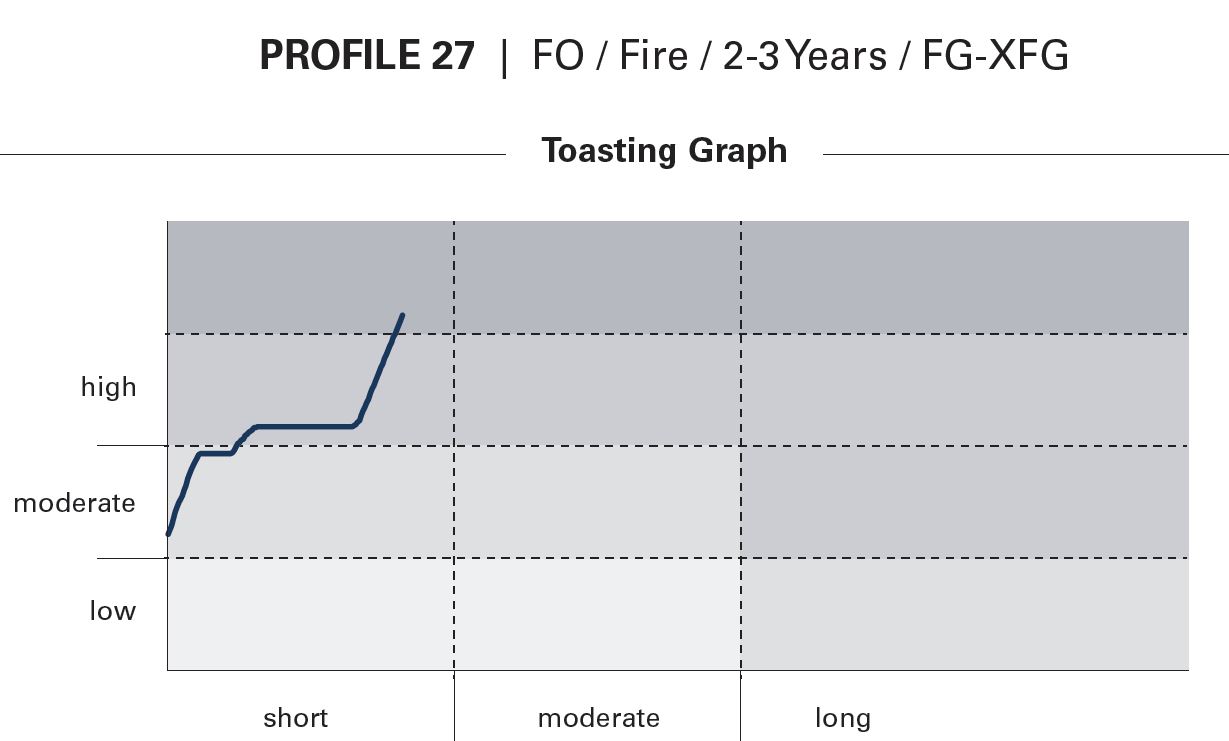

Profile 27

Sweet and fruit forward. Texture and volume on mid-palate. Complex tannin, layered finish.

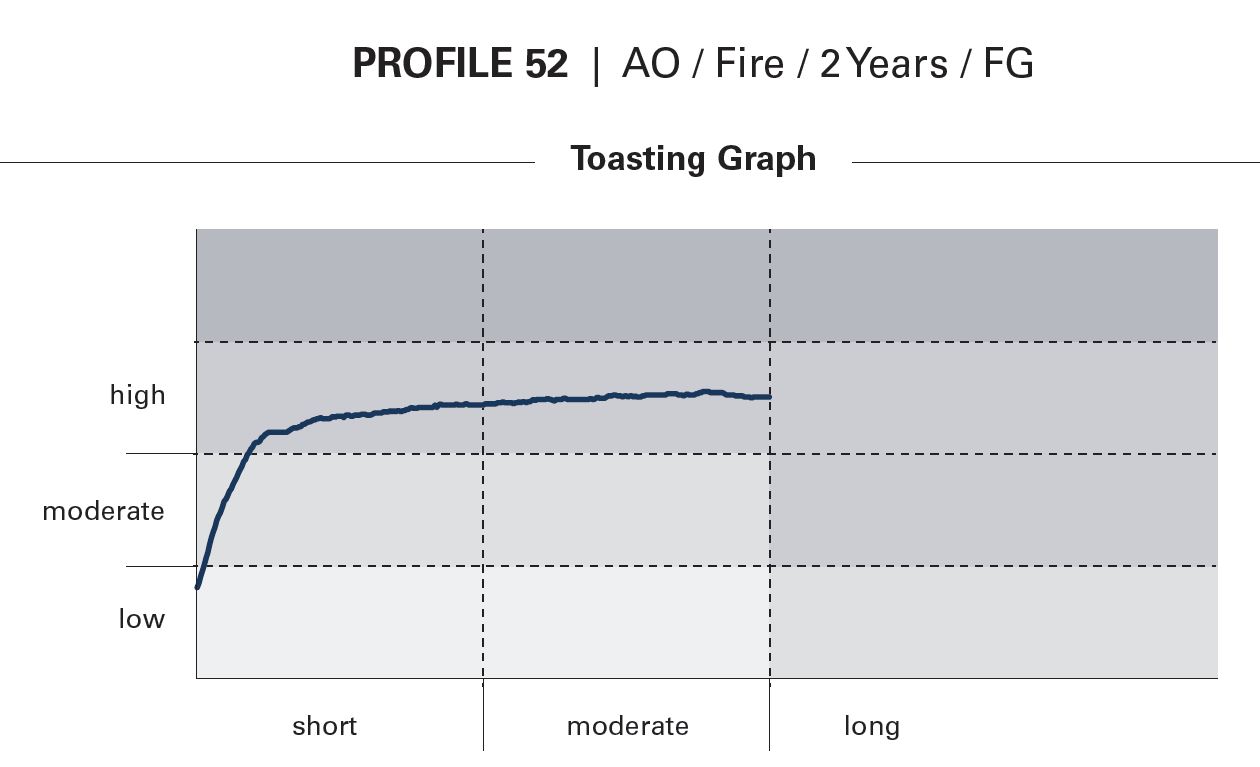

Profile 52

Intense sweet smoke flavors. Impactful entry and mid-palate. Hints of toasted marshmallow and espresso.

To start, a barrel order is entered into our system by a World Cooperage Account Manager after a consultation with the winemaker on their goals. Our team uses these same toasting curves to discuss the different Profile attributes with winemakers.

Our quality control team checks the order, then sends it down to the cooperage to be made. When it’s time for toasting, our coopers scan the bar code lasered on the barrel.

This bar code contains the order information and loads the toasting graph of the Profile specified on the order onto a display. Each one of our rotating toasting pots is equipped with an extremely accurate temperature sensor which constantly measures the temperature of the inside of the barrel during toasting.

As the toast begins, the actual time and temperature is continuously plotted on top of the toasting graph, allowing our toasters to see if they are accurately toasting the barrel. Their job is to match the toasting graph as close as possible – adding oak pieces to the fire if they need to increase the temperature or using small amounts of water to decrease the temperature.

Barrel toasting is truly a lot harder than it looks – just ask any winemaker who has toured our Missouri cooperage and tried their hand at toasting. Our coopers achieve incredibly high levels of accuracy at matching the unique toasting curve of each Profile (remember we have over 150). Of course, we have quality control measures in place to confirm the barrels are toasted to a certain degree of accuracy, thus assuring the winemaker that their barrel will taste, smell, and feel the same as it did last year.

Well, that is profiling in a nutshell - our technology for consistently delivering exactly what a winemaker is seeking. When we can deliver that, it makes for a job well done.

Want more toasting science? Geek-out on the facts below.

- Tannins are substantially destroyed by heat during toasting.

- Short, hot toasts caramelize the wood sugars on the initial layers leaving high levels of tannin intact in the subsequent layers.

- Long moderate toasts penetrate deep into the stave and degrade wood tannins at deeper layers.

- Long maturation allows the wine to penetrate below these initial layers to access the tannin for polymerisation with fruit tannin.

- Toasted oak character (caramelized sugars) are present in the top layers while the creation of vanillin goes much deeper.

Share this Post