This is the second article in our Oak 101 series. If you haven't read the first, go check it out then come back. We'll wait.

A Peek Inside of Oak

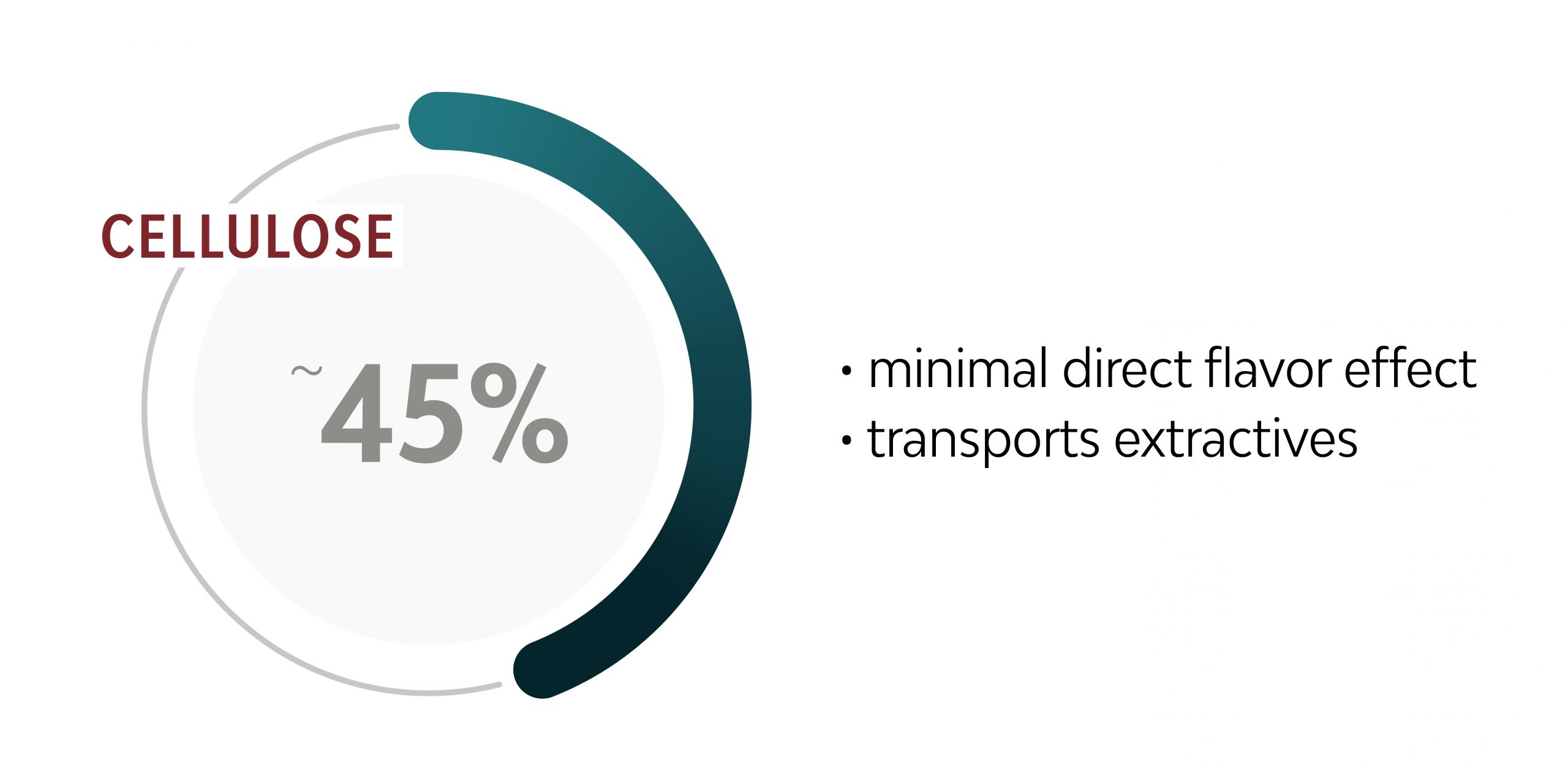

How the [Chemical] Pieces FitOak is made up of many different [chemical] parts. When working with oak for wine, it is important to understand those parts and how each contributes to the finished product. With the correct knowledge and process, the result is a deliciously aromatic and flavorful barrel that adds specific organoleptic profiles to a wine. Time to break it all down.

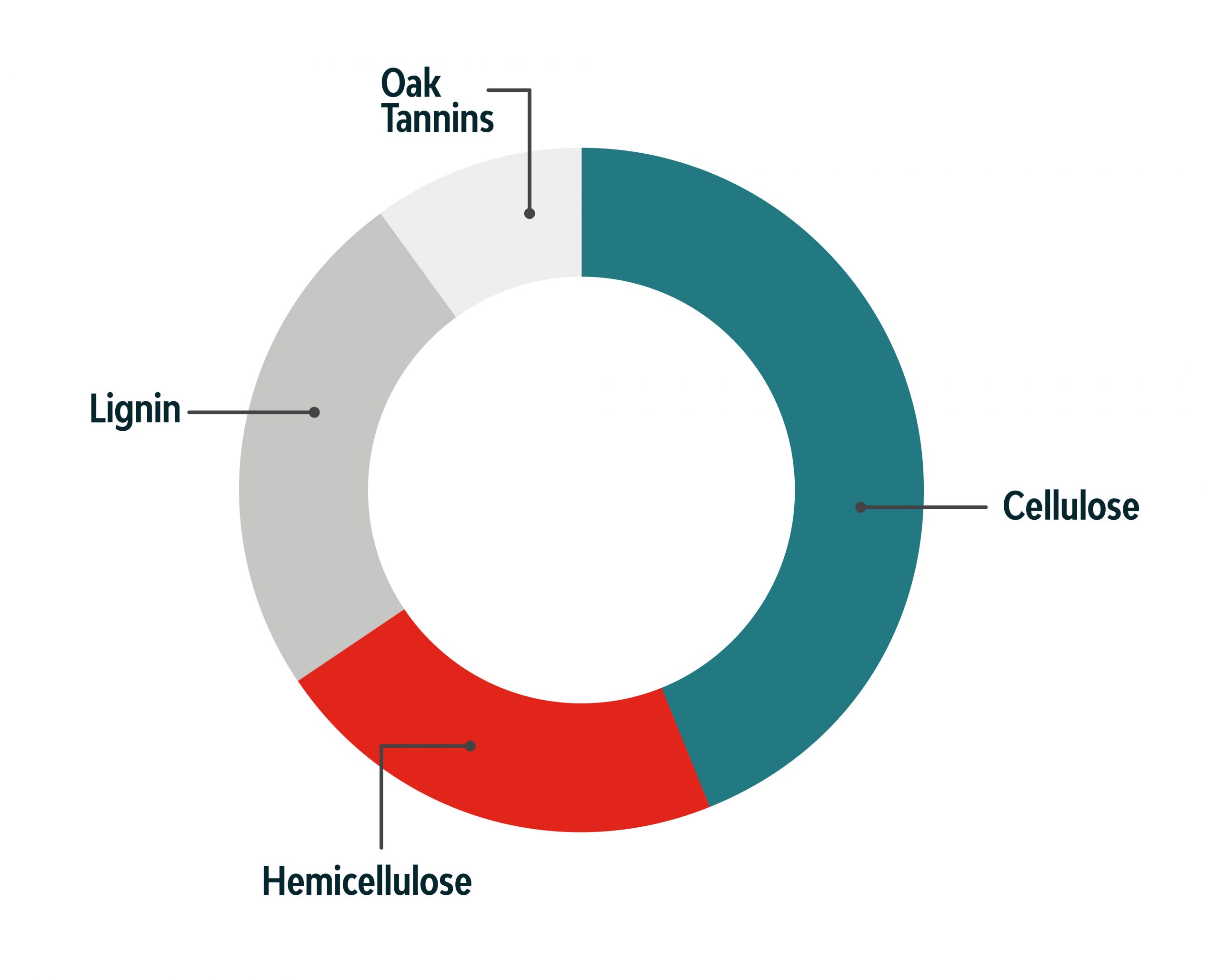

The Oak Constituents Pie Chart:

The four main constituents (aka chemical elements) of oak are: cellulose, hemicellulose, lignin and tannin.

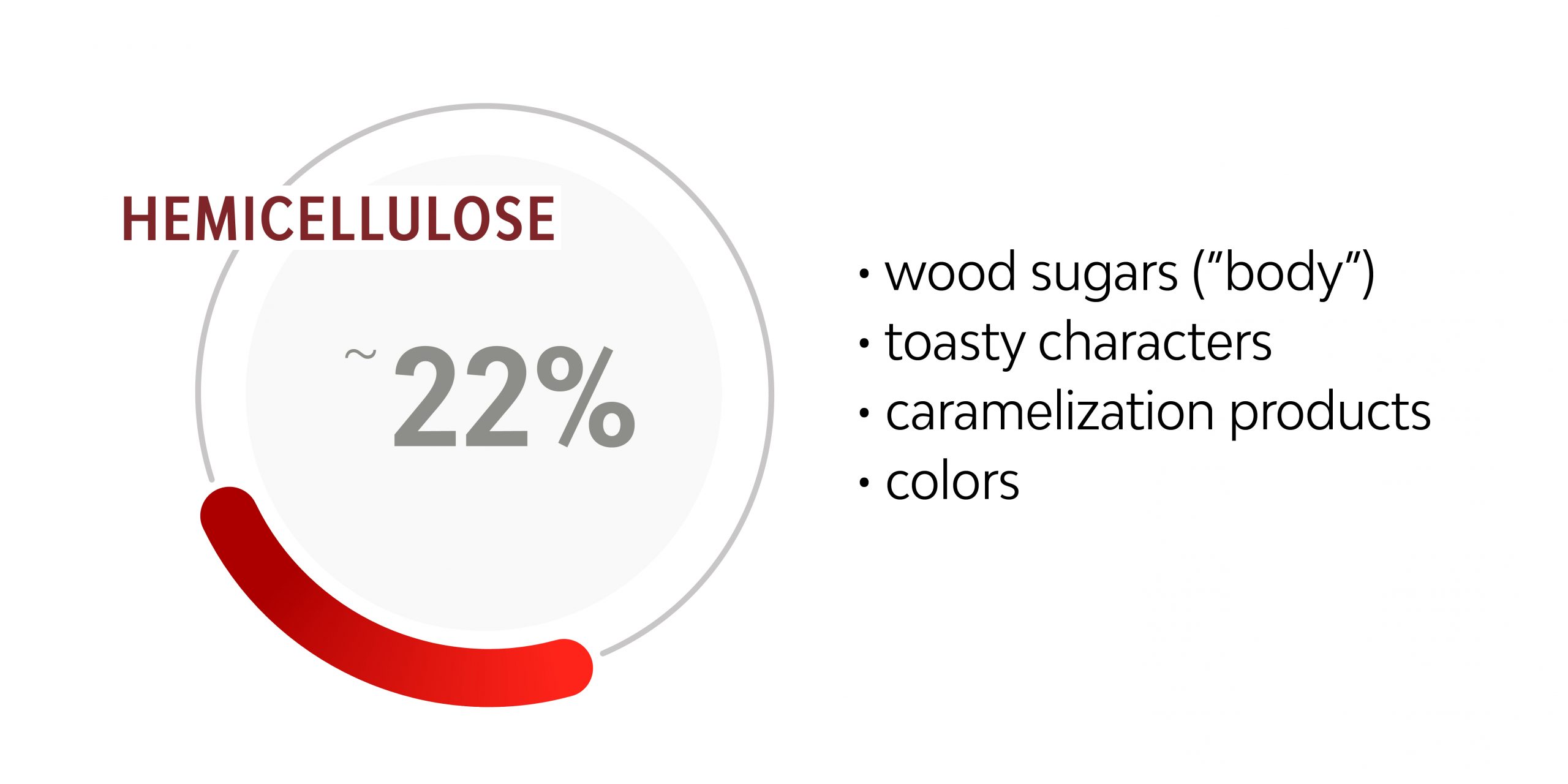

Next up is hemicellulose, comprising about 22-25% of oak. Hemicellulose is a two-dimensional polymer which consists of several simple sugars – for example xylose, rhamnose and arabinose. Don’t worry, we won’t make you pronounce them. Simple, yet important, these sugars provide the caramelization products that later result in sweet, toasty flavors that also impact the body or mouthfeel of a wine. Sweetness often equates with a smooth sensation on the palate. When you hear hemicellulose, think toasted bread, with touches of caramel, perhaps some coffee and maple syrup, wrapped up with a rounded mouthfeel. We know. Delicious, right?

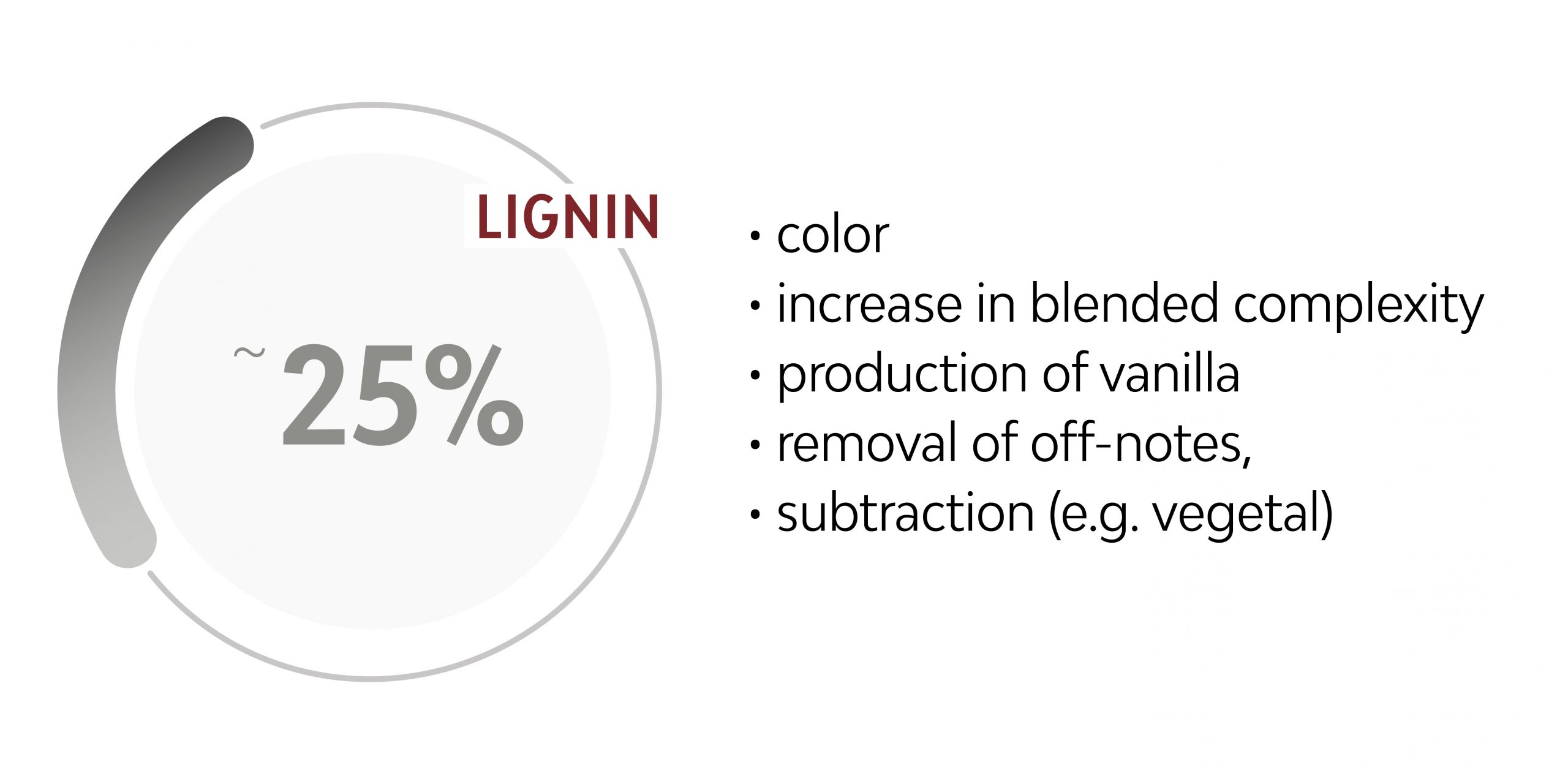

Lignin comprises about 25% of our oak constituent pie [chart]. Lignin is a three-dimensional polymer consisting of two main building blocks: guaiacyl and syringyl. Seasoning and toasting eventually release vanillin from the lignin. Some call vanillin “cat nip for humans” and it is great for developing complex flavors in wines. However, be careful – as you continue to apply energy (heat) to the lignin, spice flavors will develop and if you breakdown the lignin too far, you can create steam volatile phenols which leads to undesirable smoky characters. When done right, lignin can equate to essences of graham cracker, vanilla wafer, cream soda and maybe just a touch of welcome sweet smoke.

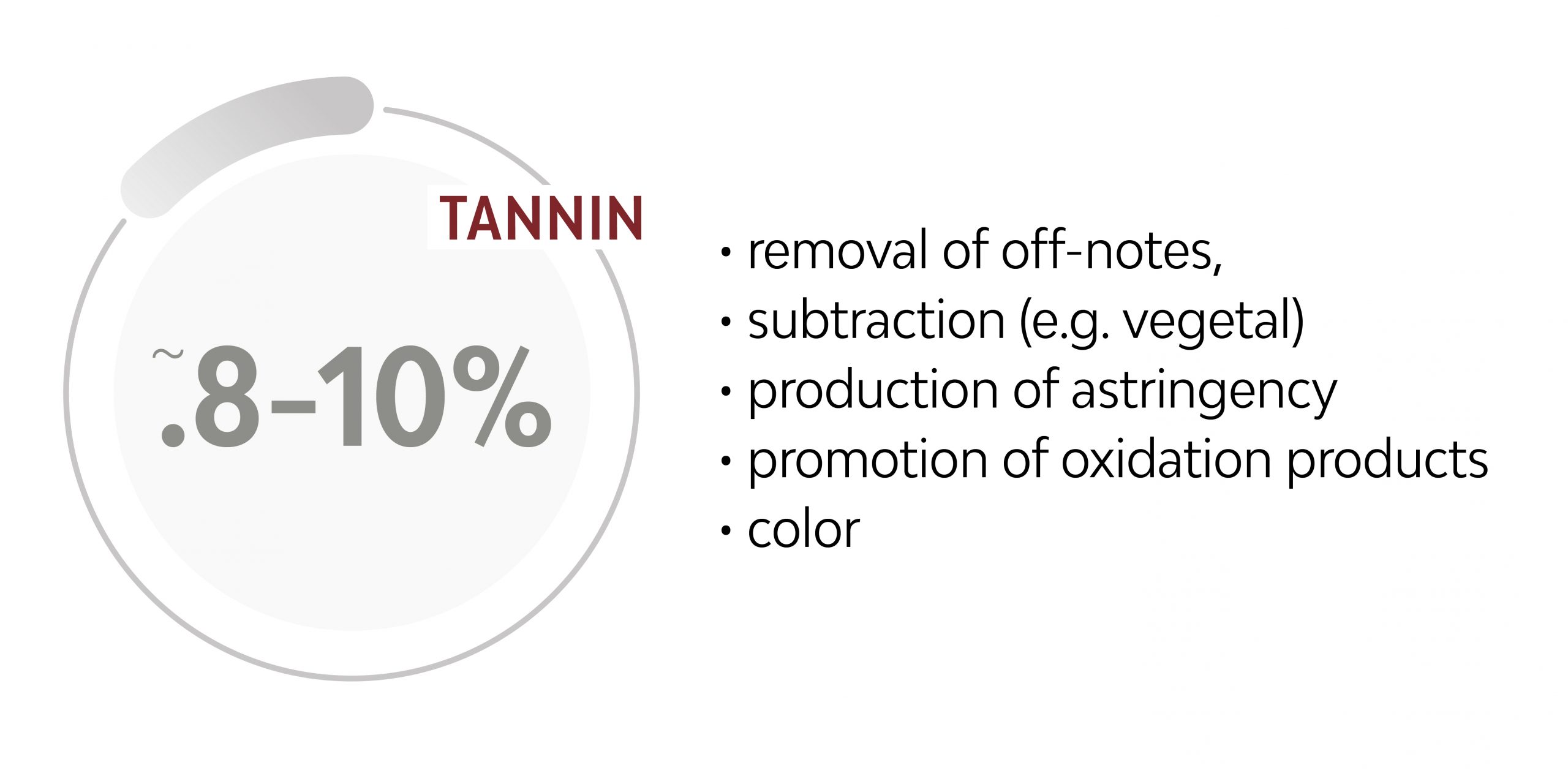

Tannin comprises somewhere between 1-10% of oak. They are a defense mechanism used by the tree to ward off predators – so predictably, they don’t taste very good. However, natural seasoning and toasting can breakdown tannins into smaller chains that are more palatable. Tannins are critical in the oxidation process and also provide structure to the wine, which in turn helps with ageability of wine as well as perceived mouthfeel. Critical stuff these tannins.

Still with us? Great. Let’s keep going.

Now what does all this mean for the final product? Well, for one thing, proper toasting is essential for barrels destined for premium wines. Knowing the exact temperature and duration at which these oak constituents break down into flavorful compounds is critical in the final profile of the barrel.

That’s where your favorite cooperage, World Cooperage, comes in. We’ve spent decades studying this stuff and refining how to coax the exact flavors winemakers seek out of each of these constituents through precise toasting. Have we told you we have over 150 ways of toasting a barrel? It’s true. We’ll do a deeper dive into the compounds that come from each of the constituents, and their contribution to the barrel flavor profile, in our next post. Stay tuned!

Share this Post